For product technical information, pricing and availability contact our sales department at:

(219) 548-3799

sales@allianceorg.com

Samarium Cobalt Magnets, developed in the 1960’s are still commonly used today because of their excellent characteristics at very high temperatures. SmCo5 and Sm2Co17 are the two main compositions of this material. They are slightly less powerful than NdFeB magnets, however they are extremely resistant to demagnetization and have the lowest reversible temperature coefficients of all magnets. Because of the high Cobalt content, they are costly and their prices tend to be volatile. Plating is typically not required for corrosion protection, however in certain applications they are plated to limit chipping. Most common usage for these materials is in the aerospace and medical industries.

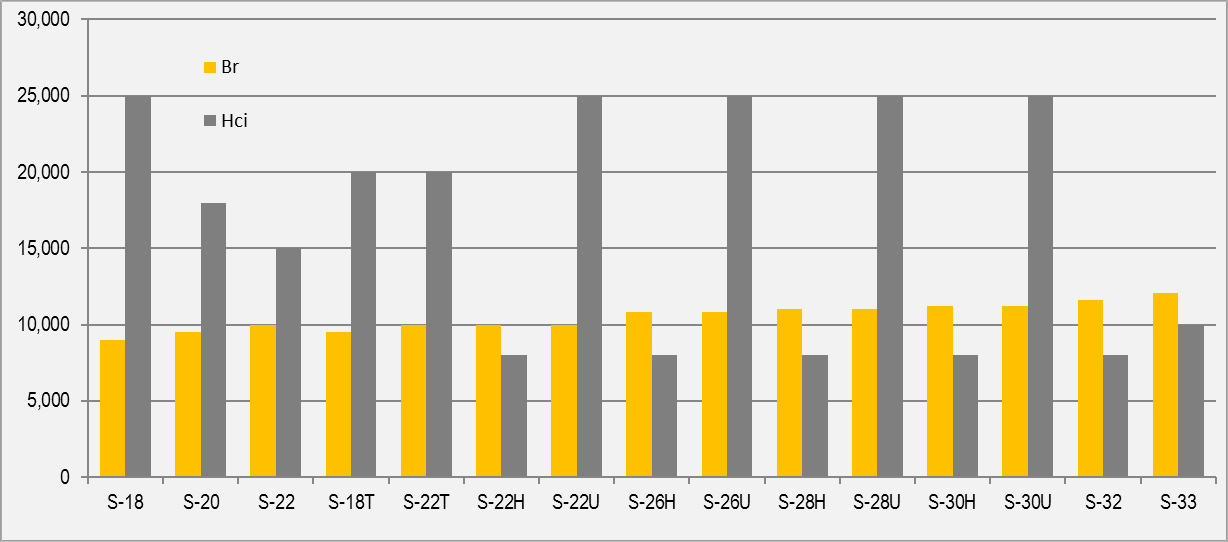

| Alliance SmCo Grades | Remanent Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Reversible Temperature Coefficients | Continuous Working Temp. | |||||

| Br (Gauss) | Hc (Oe) | Hci (Oe) | (BH)max (MGOe) | α Br | ß Hci | Tw (°C) | |||||

| Min | Max | Min | Max | Min | Max | Min | Max | %/°C | %/°C | Max | |

| S-18 | 8,000 | 9,000 | 7,800 | 8,800 | 25,000 | 35,000 | 16.0 | 20.0 | -0.05 | -0.04 | 250 |

| S-20 | 9,000 | 9,500 | 8,500 | 9,300 | 18,000 | 25,000 | 19.0 | 21.0 | -0.05 | -0.04 | 250 |

| S-22 | 9,500 | 10,000 | 9,000 | 9,500 | 15,000 | 23,000 | 21.0 | 23.0 | -0.05 | -0.04 | 250 |

| S-18T | 8,500 | 9,500 | 8,000 | 9,000 | 20,000 | 30,000 | 16.0 | 20.0 | -0.01 | -0.04 | 350 |

| S-22T | 9,500 | 10,000 | 8,500 | 9,500 | 20,000 | 30,000 | 20.0 | 24.0 | -0.01 | -0.04 | 350 |

| S-22L | 9,500 | 10,000 | 6,000 | 8,000 | 6,200 | 9,000 | 20.0 | 24.0 | -0.03 | -0.04 | 250 |

| S-22H | 9,500 | 10,000 | 7,000 | 9,500 | 8,000 | 15,000 | 20.0 | 24.0 | -0.03 | -0.04 | 250 |

| S-22U | 9,500 | 10,000 | 9,000 | 10,000 | 25,000 | 35,000 | 20.0 | 24.0 | -0.03 | -0.04 | 300 |

| S-26L | 10,000 | 10,800 | 6,000 | 8,000 | 6,200 | 9,000 | 24.0 | 28.0 | -0.03 | -0.04 | 250 |

| S-26H | 10,000 | 10,800 | 7,000 | 10,500 | 8,000 | 15,000 | 24.0 | 28.0 | -0.03 | -0.04 | 250 |

| S-26U | 10,000 | 10,800 | 9,500 | 10,500 | 25,000 | 35,000 | 24.0 | 28.0 | -0.03 | -0.04 | 300 |

| S-28L | 10,400 | 11,000 | 6,000 | 8,000 | 6,200 | 9,000 | 26.0 | 30.0 | -0.03 | -0.04 | 250 |

| S-28H | 10,400 | 11,000 | 7,000 | 10,500 | 8,000 | 15,000 | 26.0 | 30.0 | -0.03 | -0.04 | 250 |

| S-28U | 10,400 | 11,000 | 9,500 | 10,500 | 25,000 | 35,000 | 26.0 | 30.0 | -0.03 | -0.04 | 300 |

| S-30L | 10,800 | 11,200 | 6,000 | 8,000 | 6,200 | 9,000 | 28.0 | 31.0 | -0.03 | -0.04 | 250 |

| S-30H | 10,800 | 11,200 | 7,000 | 10,500 | 8,000 | 15,000 | 28.0 | 31.0 | -0.03 | -0.04 | 250 |

| S-30U | 10,800 | 11,200 | 10,000 | 10,800 | 25,000 | 35,000 | 28.0 | 31.0 | -0.03 | -0.04 | 300 |

| S-32 | 11,000 | 11,600 | 7,000 | 10,500 | 8,000 | 15,000 | 30.0 | 33.0 | -0.03 | -0.04 | 250 |

| S-33 | 11,300 | 12,100 | 8,500 | 11,500 | 10,000 | 22,000 | 29.0 | 34.0 | -0.04 | -0.25 | 250 |

| Alliance SmCo Grades | Density | Tensile Strength | Modulus of Elasticity | Thermal Expansion Coefficient /°C | Electrical Resistivity | Curie Temperature | |||||

| g/cm3 | lbs/in3 | psi | Pa x 106 | psi x 106 | Pa x 109 | ǁ to M | Ʇ to M | Ω-cm x10-6@ 20 C | °C | ||

| S-18 | 8.4 | 0.303 | 6,000 | 41 | 23 | 159 | 6.0x10-6 | 1.3x10-5 | 53.0 | 750 | |

| S-20 | 8.4 | 0.303 | 6,000 | 41 | 23 | 159 | 6.0x10-6 | 1.3x10-5 | 53.0 | 750 | |

| S-22 | 8.4 | 0.303 | 6,000 | 41 | 23 | 159 | 6.0x10-6 | 1.3x10-5 | 53.0 | 750 | |

| S-18T | 8.4 | 0.303 | 6,000 | 41 | 23 | 159 | 6.0x10-6 | 1.3x10-5 | 53.0 | 750 | |

| S-22T | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 750 | |

| S-22L | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-22H | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-22U | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-26L | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-26H | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-26U | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-28L | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-28H | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-28U | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-30L | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-30H | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-30U | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-32 | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |

| S-33 | 8.4 | 0.303 | 5,000 | 35 | 17 | 117 | 8.0x10-6 | 1.1x10-5 | 86.0 | 825 | |