For product technical information, pricing and availability contact our sales department at:

(219) 548-3799

sales@allianceorg.com

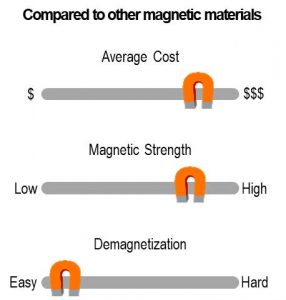

Alnico Magnets, the oldest modern magnets, were used extensively in all industries until the introduction of Ferrites in the early 1950’s. They are available by either Cast or Sintered production processes and are primarily made of Aluminum, Nickel and Cobalt. Because of their heavy Cobalt content, prices are somewhat volatile. Alnico magnets are more susceptible to demagnetization than other magnet materials and therefore have limited applications. However, because of their high pull strength they are used in lifting or holding devices and in certain sensor applications which require operation at high temperatures.

| Alliance Alnico Grades | Remanent Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Reversible Temperature Coefficients | Continuous Working Temp. | |||||

| Br (Gauss) | Hc (Oe) | Hci (Oe) | (BH)max (MGOe) | α Br | ß Hci | Tw (°C) | |||||

| Min | Max | Min | Max | Min | Max | Min | Max | %/°C | %/°C | Max | |

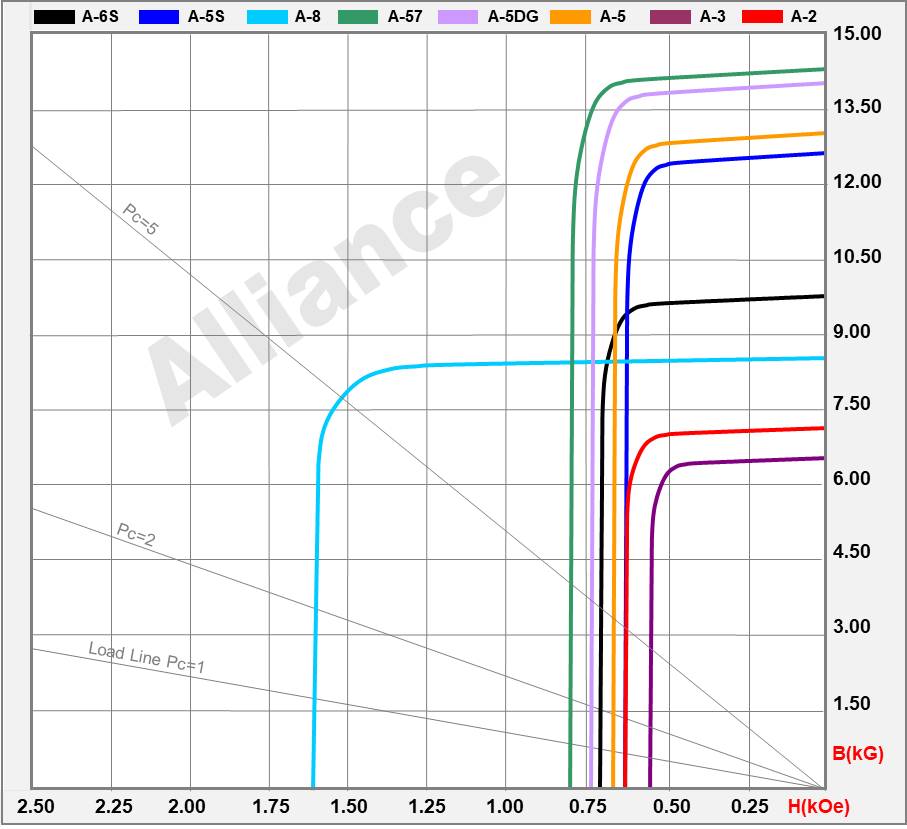

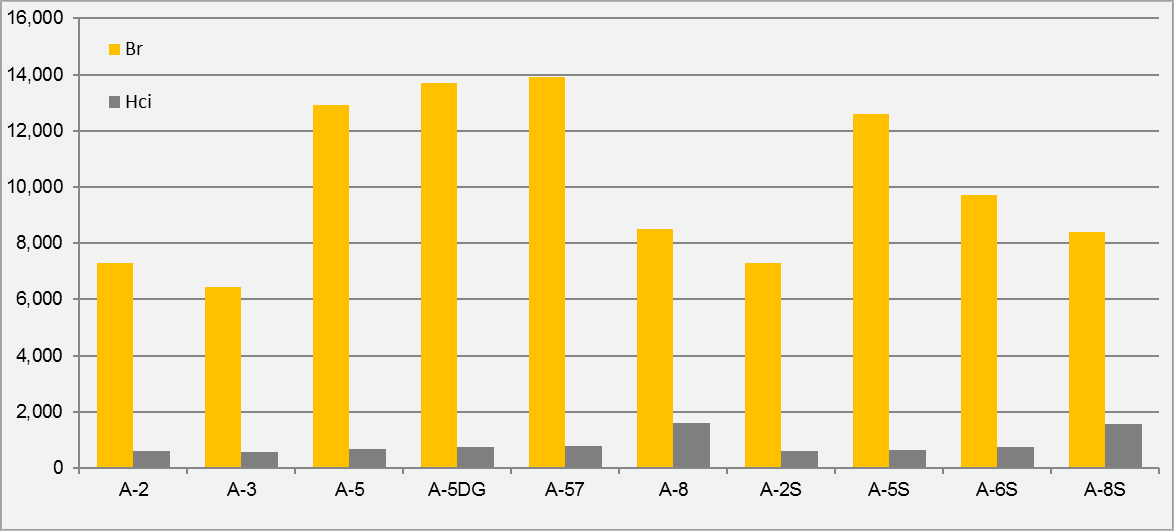

| A-2 | 6,800 | 7,300 | 550 | 600 | 570 | 620 | 1.5 | 1.7 | -0.03 | -0.02 | 450 |

| A-3 | 6,000 | 6,450 | 500 | 550 | 520 | 570 | 1.2 | 1.5 | -0.03 | -0.02 | 500 |

| A-5 | 12,000 | 12,900 | 600 | 660 | 620 | 680 | 4.5 | 5.0 | -0.02 | 0.01 | 525 |

| A-5DG | 12,800 | 13,700 | 680 | 730 | 690 | 740 | 6.0 | 6.6 | -0.02 | 0.01 | 525 |

| A-57 | 13,000 | 13,900 | 700 | 750 | 720 | 770 | 6.5 | 7.2 | -0.02 | 0.01 | 525 |

| A-8 | 7,900 | 8,500 | 1,450 | 1,550 | 1,500 | 1,600 | 5.3 | 5.9 | -0.02 | 0.01 | 550 |

| A-2S | 6,800 | 7,300 | 550 | 600 | 570 | 620 | 1.5 | 1.7 | -0.03 | -0.02 | 450 |

| A-5S | 11,800 | 12,600 | 600 | 650 | 610 | 660 | 4.2 | 4.5 | -0.02 | 0.01 | 525 |

| A-6S | 9,000 | 9,700 | 680 | 730 | 690 | 740 | 3.4 | 3.8 | -0.02 | 0.01 | 525 |

| A-8S | 7,800 | 8,400 | 1,430 | 1,530 | 1,480 | 1,580 | 4.6 | 5.1 | -0.02 | 0.01 | 550 |

| A-#: CAST ALNICO A-#S: SINTERED ALNICO | |||||||||||

| Alliance Alnico Grades | Density | Tensile Strength | Transverse Rupture Modulus | Thermal Expansion Coeffiecient | Electrical Resistivity | Curie Temperature | |||||

| g/cm3 | lbs/in3 | psi | Pa x 106 | psi | Pa x 106 | ǁ to M 10-6/°C | Ω-cm x10-6@ 20 C | °C | |||

| A-2 | 7.10 | 0.256 | 3,000 | 21 | 7,000 | 48 | 12.40 | 65.00 | 810 | ||

| A-3 | 6.90 | 0.250 | 12,000 | 83 | 23,000 | 158 | 13.00 | 60.00 | 840 | ||

| A-5 | 7.30 | 0.264 | 5,400 | 37 | 10,500 | 72 | 11.40 | 47.00 | 860 | ||

| A-5DG | 7.30 | 0.264 | 5,200 | 36 | 9,000 | 62 | 11.40 | 47.00 | 860 | ||

| A-57 | 7.30 | 0.264 | 5,000 | 34 | 8,000 | 55 | 11.40 | 47.00 | 860 | ||

| A-8 | 7.30 | 0.264 | 10,000 | 69 | 30,000 | 207 | 11.00 | 53.00 | 860 | ||

| A-2S | 6.80 | 0.246 | 65,000 | 448 | 70,000 | 483 | 12.40 | 68.00 | 810 | ||

| A-5S | 6.90 | 0.250 | 50,000 | 345 | 55,000 | 379 | 11.30 | 50.00 | 860 | ||

| A-6S | 6.90 | 0.250 | 55,000 | 379 | 100,000 | 689 | 11.40 | 54.00 | 860 | ||

| A-8S | 7.00 | 0.252 | 50,000 | 345 | 55,000 | 379 | 11.00 | 54.00 | 860 | ||

| A-#: CAST ALNICO A-#S: SINTERED ALNICO | |||||||||||